In previous blogs we mentioned that there are different factors affecting proper functioning of the lip seal. In this blog we highlight the factor temperature. Both the temperature of the lubricant under the lip, as well as the temperature in the tip of the lip, are important to the seal’s lifetime and reliability.

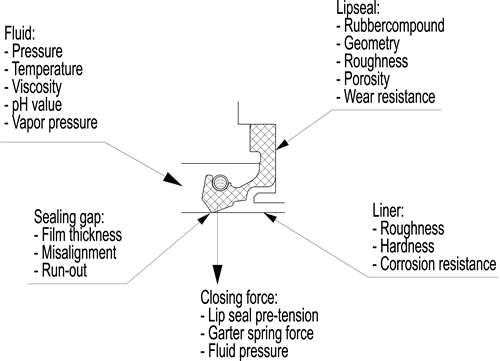

Figure 1. Factors affecting the functioning of the lip seal

What is a sealing gap?

As can be seen in figure 1, there are different factors affecting proper functioning of the lip seal. For a radial lip seal, the sealing function depends on the mechanism that is capable of bringing a hydrodynamic lubricating film between the lip seal tip and its counter surface on the liner. During running in, the lip seal tip will wear and the sealing edge will be formed and roughened. The area occupied with the lubricating film is called the sealing gap. Both the temperature of the lubricant under the lip as well as the temperature in the tip of the lip seal are important to the seal’s lifetime and reliability.

FAILURE MODES DUE TO EXCEEDING THE MAXIMUM PERMITTED TEMPERATURE

There are several failure modes that affect proper functioning of the lip seal, when the sealing gap temperature exceeds the maximum allowable operating temperature. These failure modes, resulting in heat cracks or blistering, often lead to leakage and unscheduled maintenance in dry dock.

Heat cracks

When a lip seal operates in temperatures above the operating limit, it is likely that heat cracks will arise. Heat cracks are small axial cracks that are visible on the lip seal edge, caused by hardening of the compound. If the lip seal has hardened it is also possible for breakouts on the sealing edge to occur. Heat cracks and breakouts will inevitably lead to leakage.

Blistering

With regard to the water-facing lip seals, another phenomenon can occur; water vapourises under heat. This vapour can enter the elastomer material and when the water condensates within the molecular structure of the elastomer blisters will be formed, affecting the sealing function of the lip seal.

What causes an increasing temperature?

There are different factors responsible for increasing the temperature in the sealing gap. One is the load on the lip seal’s contact zone and another factor is the rotations per minute (RPM). The factors are explained below.

The load on the lip seal's contact zone

One factor responsible for increasing the temperature in the sealing gap is the load on the lip seal’s contact zone. The load is a combination of the fluid pressure difference across the lip seal, the garter spring force and the pre-tension of the lip seal itself. The load distribution together with the lip seal geometry and the rotation of the liner are essential for a lubricating film to establish.

Fluid pressure

The fluid pressure difference across the lip seal is the difference between the fluid pressure distributed on the front of the lip seal and the fluid pressure that exists on the back of the lip seal. The greater the fluid pressure difference, the greater the friction and temperature increase will be. The fluid pressure is, in case of a water-facing lip seal, the water pressure as a result of the water column above the shaft centreline, or in case of an oil-facing lip seal, the oil pressure as a result of the distance in height between the oil level in the header tank and the shaft centreline.

Garter spring force

The garter spring is used to maintain pressure on the front of the lip seal for a proper pressure distribution on the circumference of the lip seal tip in case fluid pressure is low. The garter spring has a big influence on the total pressure distribution at shallow draughts. At deeper draughts the pressure distribution by the lip seal garter spring is marginal.

The pre-tension of the lip seal

The bore of the lip seal is smaller than the outer diameter of the liner. This gives an initial pre-tension and will become less over time, depending on the elastomer’s physical properties.

RPM

The RPM of the propeller shaft is another factor generating heat. The greater the circumferential velocity of the liner, the greater the friction and the temperature increase; faster movement generates more heat.

What do we recommend?

The pressure difference across the lip seal and the circumferential speed of the liner are the two factors that have major influence on the temperature increase. When the temperature of the lubricant rises, the viscosity drops. This will affect the lubricating film thickness.

Use of oil

Lagersmit recommends using oils with a minimum ISO 3448 Kinematic Viscosity Grade of 68 cSt (mm2/s) at 40 °C.

The proper lip seal compound for your Supreme seal

The different elastomer compounds each have their own operational temperature range. NBR for example has a maximum operating temperature of 100°C. FKM can withstand higher temperatures up to 130°C. By calculating the PV-value, Lagersmit can advise the proper lip seal compound for each Supreme seal.

Supreme Ventus

Another solution to bring down the temperature is to control the pressure difference across the lip seal. For this purpose, Lagersmit developed the Supreme Ventus System. It is recommended for draughts greater than 5 metres.