Stern Tube Bearing

STERN TUBE BEARING

Our white-metal lined stern tube bearings are based on proven technology and can be customized with various materials and options.

Advantages

Design based on proven technology

Delivered pre-machined for flexibility on-site

Suitable for either new-build or retrofit applications

HOW A STERN TUBE BEARING WORKS

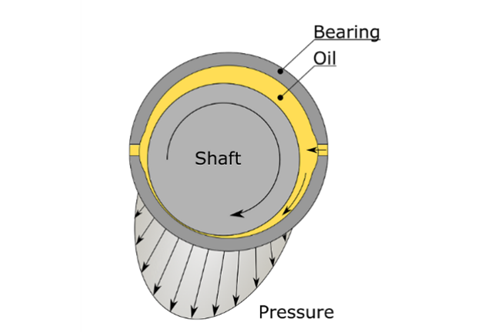

The function of the stern tube bearings is to carry the radial loads of the propeller shaft and to protect the shaft against wear. In the case of an oil-lubricated bearing, this is achieved by creating an oil film between the bearing and the propeller shaft. When the propeller shaft is rotating, nearby oil will follow the circumferential movement of the propeller shaft.

At sufficient shaft speed, the oil will flow from the supply holes in the bearing along with the shaft towards the bottom of the bearing. Here it is forced between the narrowing space between the bearing and shaft, which creates lift. When the shaft speed is high enough, there will be no metallic contact between the shaft and bearing. This principle is called hydrodynamic lubrication.

MATERIALS & OPTIONS

Our stern tube bearings are suitable for oil- and grease-lubricated systems with shaft diameters varying from 70mm to approximately 900mm. Lagersmit bearings can be delivered with a class approval/certificate upon request and have several options;

Aft, intermediate or forward stern tube bearings

Temperature sensor for measuring bearing metal temperature

Different grades of cast iron

Different types of white metal, including lead- and tin-based white metal

Delivery in pre-machined condition, with or without oil supply holes and longitudinal grooves

The bearings are made from a cast iron bush with a white metal lining inside. There are two types of white metal;

- lead-based

- tin-based

In most cases, lead-based white metal will be sufficient for stern tube bearing applications and will also be the most economical option. For ice-class, navy vessels or environmental regulations we recommend tin-based white metal lining. The tin-based white metal is more suitable when dynamic loads can occur.