SABIC

LIQUIDYNE® FOR COOLING WATER PUMPS

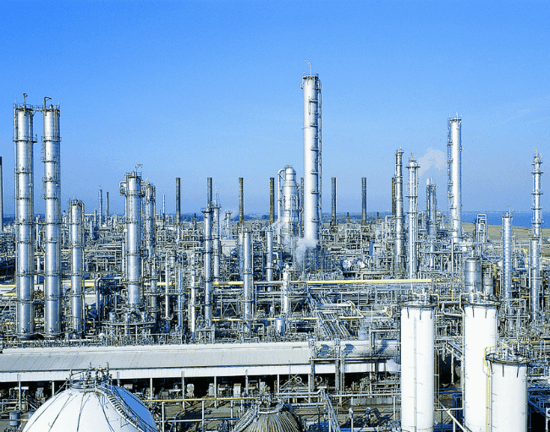

SABIC

A number of years ago, SABIC and Lagersmit teamed up as part of a Global Framework Agreement. This collaboration started in 2004 with the successful installation of a Liquidyne® seal for a cooling-water pump from SABIC’s BUFA plant.

The exceptional performance of the seal led to the inclusion of Liquidyne in the Engineering Practices. Liquidyne was also used to strengthen the operations in the Olefins 3 and 4 plants. The seal performed so well that the Liquidyne was almost forgotten. At the end of 2014, the seal was back in the spotlight during maintenance of the pump. ‘Thanks to these achievements, we delivered on and surpassed our goal of providing “Peace of Mind” regarding our cooling-water pumps,’ says SABIC.

REAL ENERGY SAVINGS

On SABIC Innovative Plastics Utilities’ site in Bergen op Zoom, we have changed the gland packings of the 1 MW cooling water pumps into Liquidyne seals. Replacing the shaft seal led to the following results for SABIC:

Costs

Due to the minimized friction of the Liquidyne seal, the pump consumes 12.6% less power.

Availability

Pump availability increased into 99.5%, meaning an improvement of 53%.

Reliability

The lifetime of the Liquidyne seal was extended to between six and eight years.

Environment Health Safety

No maintenance and adjusting needed during operation. No leakage – safe and clean working environment