TABLE OF CONTENTS

SEALING SOLUTIONS FOR

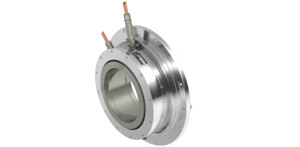

- Effective separation of water and lubricants

- Available in split type

- Highly corrosion resistant

- Complies with the VGP and VIDA regulations

- 24/7 condition monitoring

- Zero emissions of oil

- Extra safety due to its redundant lip seal

- Effective separation of water and lubricants

- Available in split type

- Small build-in length

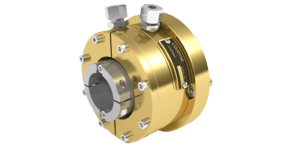

- Special thruster design

- Condition monitoring

- Safety measure preventing water ingress

- Special thruster design

- Condition monitoring

- Predictable lifetime due to condition monitoring

- Low power consumption

- Maximised maintenance intervals

- Especially for heavily polluted pump water

- Maximised maintenance intervals

- Predictable lifetime due to condition monitoring

- Especially for heavily polluted pump water

- Maximised maintenance intervals

- Predictable lifetime due to condition monitoring

- Ensures a safe return to port

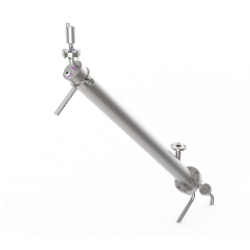

- Allows large radial (5 mm) and axial (30 mm) play

- Can be used for low- and high-speed shafts

- Complete package including seals, bearings and piping

- Easy installation

- Suitable for either new-build of retrofit applications

- Maintenance can be planned and intervals maximised

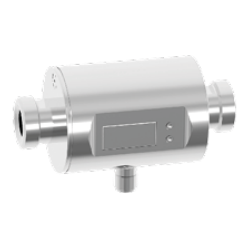

- Better control and accuracy of flush measurement

- The flow meter can be applied to all Liquidyne seals

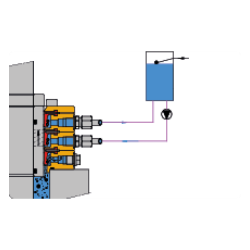

- Closed flush system

- Condition monitoring

- Minimal consumption

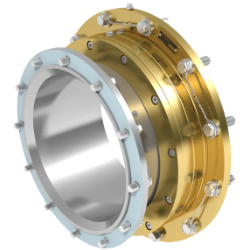

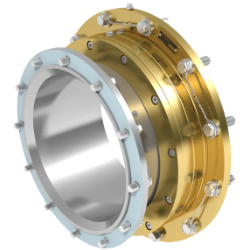

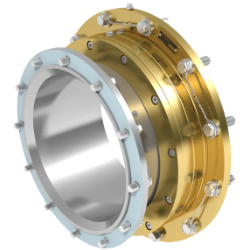

LIQUIDYNE® AND SUPREME® SEALS

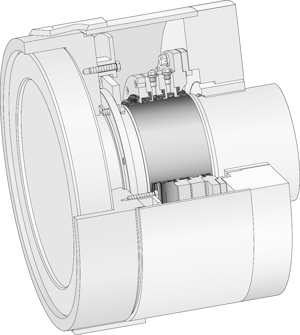

When it comes to dredging equipment, reliability is the key. You need to keep the dredging process going 24 hours a day, 7 days a week. The water-lubricated Liquidyne® seal was initially developed for heavy-duty dredge pumps. Besides having a stable dredger pump, it is also important to keep your dredging vessel going. To make this possible, we supply our own propulsion and cutter shaft Supreme® seals.

Both Liquidyne and Supreme seals were specially developed for the dredging industry where superb durability matters the most. Use the Liquidyne and Supreme combination in your dredging operation and take the next step in reliability and performance. You can find our sealing solutions for dredgers on the following applications:

- Dredge pumps

- Slurry pumps

- Jet pumps

- Booster pumps

- Process pumps

- Deep well pumps

- Cooling-water pumps

- Bulkheads

- Cutter ladders

- Thrusters

- Stern tubes

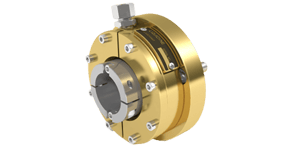

CUSTOMISED OPTIONS

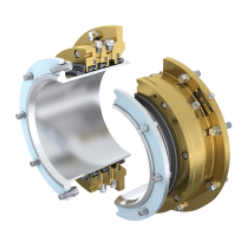

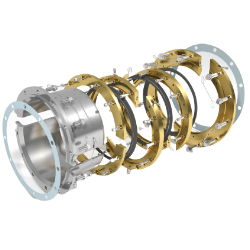

Complemented with a broad range of options, the Supreme® seals can be fully customised to your specific sealing need to guarantee your Peace Of Mind.

OVERVIEW

- Net cutters

- Wire winders (popular option)

- Cathodic protection (popular option)

- NBR/FKM lip seals

- Hastelloy® C4 springs

- Distance ring

- Dirt barrier (popular option)

- Hard Metal Liner coating (popular option)

- Oil Collector Ring

.jpg?width=200&name=logo-berg-propulsion%20(1).jpg)