TABLE OF CONTENTS

SEALING SOLUTIONS FOR

- Effective separation of water and lubricants

- Available in split type

- Highly corrosion resistant

- Complies with the VGP and VIDA regulations

- 24/7 condition monitoring

- Zero emissions of oil

- Most chosen option for retrofit

- Extra safety against oil leakage

- Complies with the VGP and VIDA regulations

- Targeted design for larger yachts, cruise ships and ferries

- 24/7 condition monitoring

- Complies with the VGP and VIDA regulations

- Extra safety due to its redundant lip seal

- Effective separation of water and lubricants

- Available in split type

- Targeted design for inland vessels

- Suitable for small shaft diameters

- Available in split type

- Small build-in length

- Special thruster design

- Condition monitoring

- Safety measures preventing water ingress

- Special thruster design

- Condition monitoring

- Environmentally friendly solution in line with VGP/VIDA regulations

- Extra safety through the incorporated inflatable seal

- Optimised and extended seal lifetime

- Automatically adapts to the shaft’s radial play if the bearings wear down

- The seals can handle a radial play up to 5 mm

- Environmentally friendly solution in line with VGP/VIDA regulations

- Available in split type

- Durable

- Reliable

- Extra protection for larger yachts and cruise ships

- Prevents water ingress into the drive train

- Highly corrosion resistant

- Special rudder stock design

- Prevents water ingress into the rudder stock bearings

- Fully customised upper and lower rudder stock bearing seals

- Ensures a safe return to port

- Allows large radial (5 mm) and axial (30 mm) play

- Can be used for low- and high-speed shafts

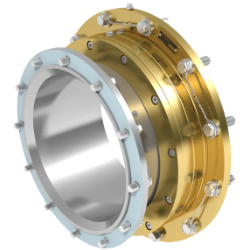

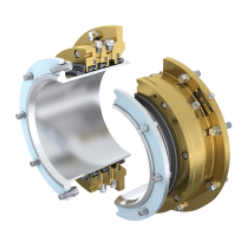

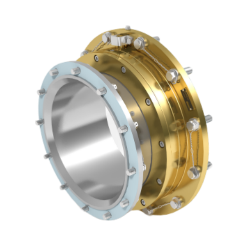

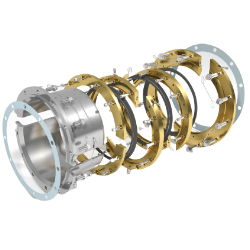

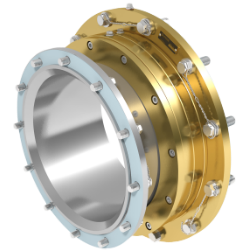

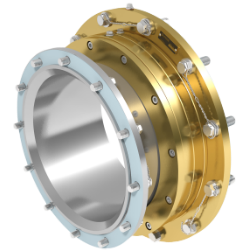

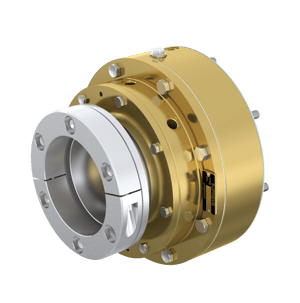

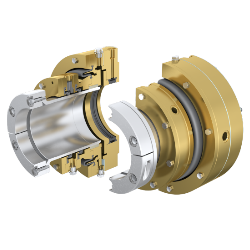

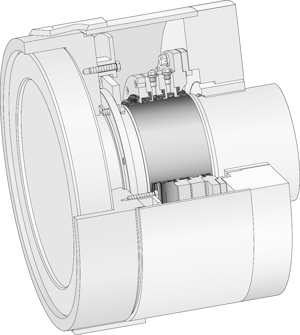

SUPREME® PROPULSION SEALS

We believe a seal should deliver top performance, keep you going, and offer you Peace of Mind. This idea led to the development of the Supreme seal. Introduced in the 1980s and further developed ever since Supreme seals offer a ‘plus’ to many propulsion systems and vessels worldwide.

It is important that all sealing components are of the highest quality and are perfectly compatible with each other. In the production facility at our headquarters in Alblasserdam, the Netherlands, we make sure our Supreme seals meet these high standards – adding quality and reliability to your propulsion system.

The Supreme stern tube seals and Supreme thruster seals are produced with high-quality housing parts, lip seals and liners. Our Modular, Made-to-Measure philosophy enables us to deliver customer-specific designs combined with short quotation, lead and delivery times. In addition, the Supreme seals are suitable for both new-build and retrofit applications.

The list of advanced options such as a Hard Metal Layer (HML) coating for extra durable liners and Environmentally Acceptable Lubricant (EAL) compatible lip seals allows you to customize your seal design to your preferences.

THE FOLLOWING BENEFITS APPLY TO ALL SUPREME SEALS:

Effective separation of water and lubricants

Bonding in situ possible

Optimised Total Cost of Ownership

Available with a broad range of options

Suitable for both new-build and retrofit applications

Highly corrosion resistant

Modular, Made-to-Measure

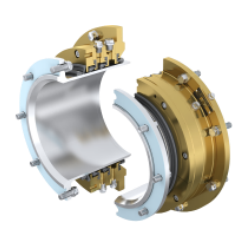

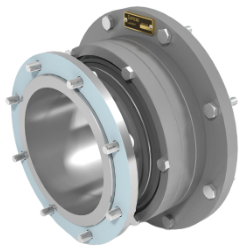

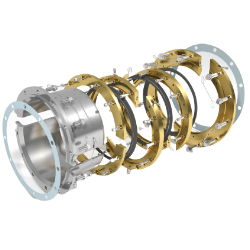

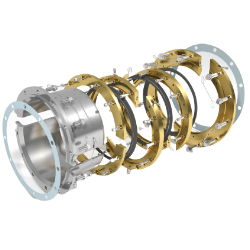

CUSTOMISED OPTIONS

Complemented with a broad range of options, the Supreme® seals can be fully customised to your specific sealing need to guarantee your Peace Of Mind.

OVERVIEW

Net cutters

Wire winders (popular option)

Cathodic protection (popular option)

NBR/FKM lip seals

Hastelloy® C4 springs

Distance ring

Dirt barrier (popular option)

Hard Metal Liner coating (popular option)

Oil Collector Ring

OUR CUSTOMERS