TABLE OF CONTENTS

SEALING SOLUTIONS FOR

- Effective separation of water and lubricants

- Available in split type

- Highly corrosion resistant

- Robust seal design

- Maximised maintenance intervals

- Predictable lifetime due to condition monitoring

- Dedicated R&D department

- Custom design engineering

- Close cooperation with our customers

DURABLE PUMPING STATIONS

The Netherlands has been an outstanding player in the field of sustainable and reliable water management for years. Our seals for locks and pumping stations contribute to water control.

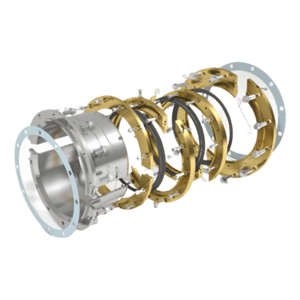

Released in 1983, the water-lubricated Liquidyne® pump shaft seal was initially intended for heavy-duty dredge pumps. Thanks to its robust design, the seal can handle above-average axial and radial play. The Liquidyne has a predictable lifetime due to the condition monitoring function. In addition, the pump shaft seal is also environmentally friendly thanks to the water-lubricated system that saves energy through reduced friction on the shaft. This makes the Liquidyne a durable solution for pumping stations.

The Liquidyne pump shaft seals are an alternative to industrial gland packing and mechanical seals. Discover the differences via our blogs below:

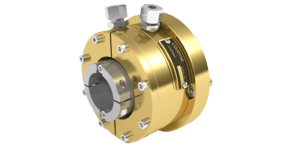

LIQUIDYNE 3-STAGE

The Liquidyne 3-Stage is the best solution for pumping stations where a long service life is required.

ADVANTAGES

- Predictable lifetime

- Energy savings

- Safe workplace

- Easy to maintain

RELIABLE LOCKS

Lock gates must be able to roll to close properly. With the shaft seals of locks, it is of great importance that water and lubricants are separated. Our Supreme® Standard seal increases the reliability of the lock.

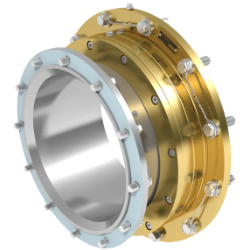

SUPREME STANDARD

The Supreme Standard is the best solution for locks where reliability and quality are required.

ADVANTAGES

- Effective separation of water and lubricants

- Robust design

- Maximized maintenance intervals