Two categories of stern tube seals

Lagersmit supplies stern tube seals for two categories; the Supreme seals for inland vessels and the Supreme seals for seagoing vessels.

The outboard or after stern tube seal is located at the aft end of the stern tube. The seal’s housing is connected to the ship’s stern tube bossing and the liner is fixed on to the propeller hub. The aft seal prevents seawater from contaminating the stern tube oil, which may possibly jeopardise the lubrication properties of the oil, leading to extensive bearing wear. The aft seal also prevents oil leaking into the marine environment.

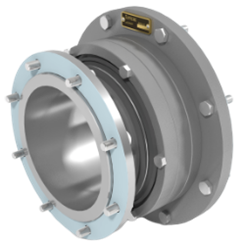

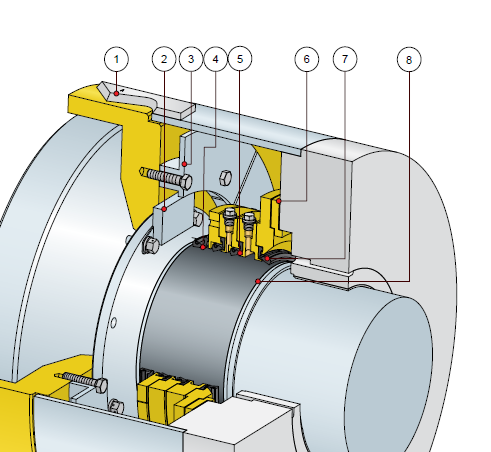

Figure 1: Supreme Inland Vessel

What we recommend for inland vessel

For inland vessels we recommend the Supreme Standard for Inland Vessels After and Forward sealing solution. The aft seal contains three lip seals. The first two lip seals form a barrier against water ingress and the third one prevents oil leakage from the stern tube into the surrounding water.

Because vessels for inland waterways don’t have to cope with highly corrosive seawater, the housing parts of the aft seal are made out of cast iron. All four housing parts of the aft seal are bolted together all at once. The same goes for the forward seal.

The inboard or forward seal is located at the forward end of the stern tube and is connected to the aft peak bulkhead inside the engine room. The forward seal contains two lip seals preventing oil leaking from the stern tube into the engine room. The chamber between the lip seals can be filled with oil or grease for lubricating the outermost lip seal.

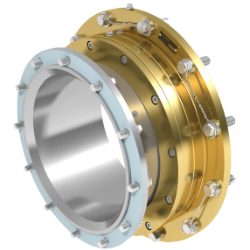

What we recommend for seagoing vessels

The Supreme Standard After (STA) and Supreme Standard Forward (STF) seal are developed for seagoing vessels. The aft seal on a seagoing vessel is in contact with the highly corrosive seawater. Therefore, the housing parts are made out of bronze. The housing parts of the Supreme Forward seal are made out of cast iron.

The STA and STF have the same configuration of the lip seals as the lip seals from the Supreme Standard for Inland Vessels and perform in the same way. The main difference, apart from the material of the aft seal, is that the housing parts are fixed independently of each other. This enables easy bonding of the lip seals when the vessel is in dry dock, saving a lot of precious time. This isn’t necessary for inland vessels, because for inland vessels it’s quite easy to remove the propeller so that the entire seal can be disconnected.

Figure 2. Supreme Standard

The STF is equipped with a lube oil tank and a scraper which is located in-between the lip seals. The scraper forces the oil to circulate through the lube oil tank, providing cooling when the shaft is turning.

How the Supreme SeaGuard aft seal extends the vessels docking interval

The SeaGuard is a modified STA, gaining an extra lip seal preventing oil leakage into the seawater. Not only will it help in safeguarding the environment, but it will also contribute to an expansion of the vessel’s docking interval. Lip seal #3s works as a spare seal and can be activated at the moment the header tank oil level drops, by closing the valve on the oil inlet pipe between lip seals #3 and #3s.

Supreme options: air-type seal

Several options can be applied to give you extra peace of mind.

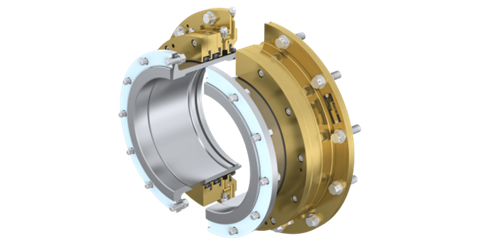

Supreme Athmos®

The Supreme Athmos ensures zero oil-emission to the environment and provides a safe operation by preventing water into the system. It’s designed for ships with a limited draught (up to five meters). If you have a yacht, inland vessel or a ferry, the Supreme Athmos is the right sealing solution for your vessel. Read more in our Supreme Athmos blog.

Figure 3. Supreme Athmos

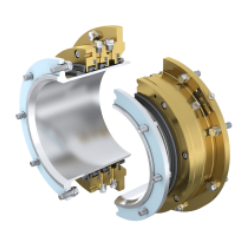

Figure 4. Supreme Ventus

The Supreme Ventus®

The Supreme Ventus air-type seal guarantees zero oil-emissions, an absolute minimum of wear and enables you to check the condition of the aft seal. It is suitable for vessels with a varying draught. Read more in our Supreme Ventus blog.

Customise your seal even further with the following options

For an overview of all the customised options, visit the Supreme Custom Design page.

Figure 5. Cross-section of a seal