The slogan ‘The Origin of Sealing Solutions’ suggests that Lagersmit only offers seals. But did you know we also supply the complete stern tube and sealing system including stern tubes and bearings? In a previous blog we gave an introduction to Lagersmit’s bearings, but this blog focuses on complete stern tube systems. Keep reading to find out more about the working principles and how our stern tube system delivers you Peace of Mind.

STERN TUBES: TO REFRESH YOUR MEMORY

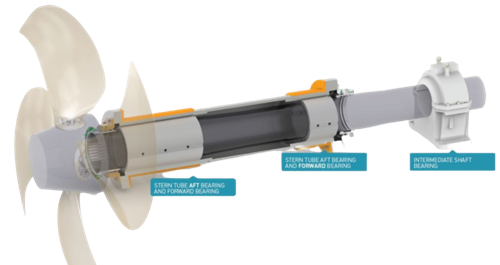

The stern tube is installed at the stern of the ship and carries the sliding bearings that are used to support the propeller shaft. The stern tube is filled with a lubrication medium and provides room for needed piping for example oil lines, temperature sensors and the Supreme Ventus® system. Seals are installed at the aft and forward end of the stern tube.

HOW IT WORKS

Every stern tube design is customised according to the customer’s requirements. Because the stern tube can be fully equipped with piping, bearings and seals, the installation can be done within a day. There are various types of stern tube systems available and when making the selection you have to take several factors into consideration.

HOW LAGERSMIT’S STERN TUBE SYSTEM DELIVERS YOU PEACE OF MIND

We offer complete stern tube systems with the bearings, piping and seals already in place. This will make the installation much easier and saves you valuable time and money. The design of the stern tube system can be customised according to your needs with a broad range of options.

Other advantages of our stern tube system: they are

- delivered fully assembled on site

- compatible with Lagersmit’s Supreme Ventus sealing system

- ready-machined in a controlled environment

- easily installed by means of a resin casting

- interfaced with Lagersmit-type seals

In addition to stern tube bearings, we also deliver intermediate shaft bearings to support longer shafts in a driveline. If an open or closed water stern tube system is required, please call us for further information.