Custom design

TABLE OF CONTENTS

CUSTOM DESIGN

We can build on a rich history of designing, producing and installing custom-designed sealing solutions. As an independent seal supplier, it’s our goal to work closely with our customers to provide them with a tailored solution that exceeds their expectations.

ONE STEP AHEAD: DEDICATED RESEARCH AND DEVELOPMENT

Our Research and Development department is continuously working on product improvements, line extensions and new products for our customers to have sustainable, reliable, green and cost-efficient sealing solutions. With our Supreme Ventus®, we have managed to improve seal performance, extend docking intervals and fulfil the Vessel General Permit (VGP) requirements.

Our R&D department spends its time on seal retrofit applications and custom-designed sealing solutions for all sorts of applications relating to marine propulsion, dredging, (clean) power generation and offshore equipment. Even if it seems there is no solution at hand, our engineers often do find one. Towards the future, Lagersmit is focusing more and more on condition monitoring of the seal and further extending the seal’s lifetime by enhancing the seal design and developing auxiliary systems.

We’re always up for a new challenge! Our R&D team enjoys exchanging ideas and creating the sealing solution from first sketch to delivery.

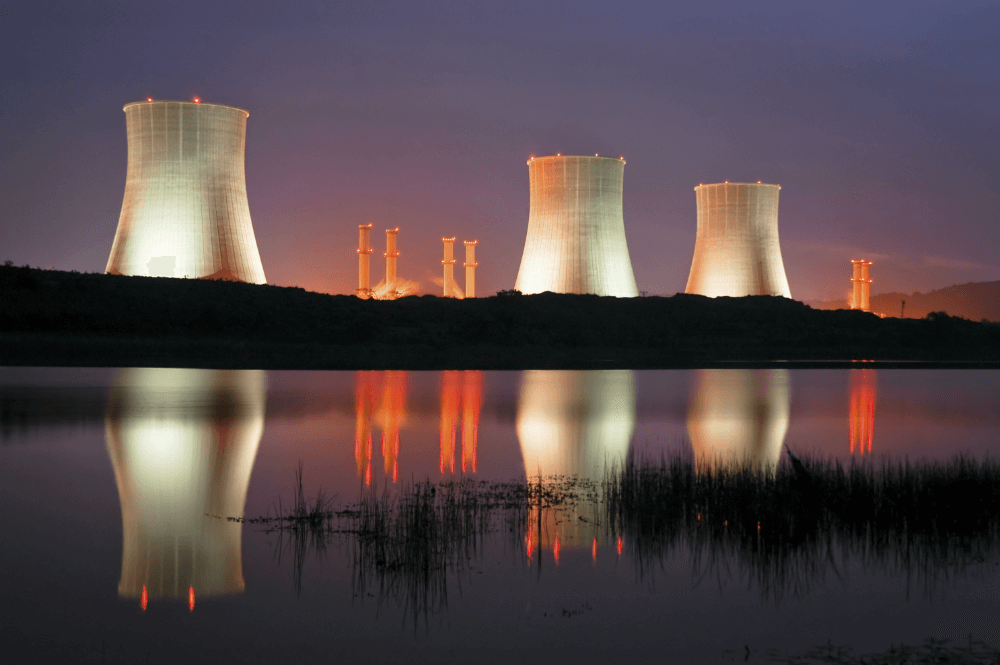

REAL CUSTOM DESIGN: LIQUIDYNE HYBRID SEAL

A special Hybrid (combination of a Supreme® and Liquidyne) has been manufactured for cooling-water pumps for nuclear reactors. A Supreme seal is installed in the cooling-water pump’s drive mechanism and used to keep out lubricant. In addition, a Liquidyne is used to ensure the water is retained in the cooling-water pump.

HOW IT WORKS

The Liquidyne Hybrid is specially designed for concrete volute pumps that are designed with a grease-lubricated roller bearing at the bottom. The Liquidyne Hybrid system consists of two parts: the pump shaft seal, which is used to seal the pump shaft of a vertical pump, and the bearing seal, which protects the pump bearing and its grease environment.

The seals are placed inline over the pump shaft. The pump shaft seal is mounted on the pump cover or housing part of an inflatable seal, whereas the bearing seal is mounted directly on the bearing housing. The bearing seal – known as Supreme® – is a grease-lubricated seal unit. A bearing seal is positioned in order to prevent water or dirt from entering the bearing housing on both sides.

The pump shaft seal is a water-flushed sealing system known as Liquidyne LDS. This system is able to withstand high and variable loads caused by circumferential velocities and pressure differences. In addition, thanks to its flexible lip seals, the pump shaft seal can continue to function at its best even with axial movement.

DESIGN

- Pump shaft seal module

- Pressure-reducing module

- Drain pipe

- Inflatable seals

- Bearing seal module

- Uses external flush to:

- Lubricate

- Clean

- Cool the seal

- Active flow to pump side