CUTTER GEAR BULKHEAD

CUTTER GEAR BULKHEAD

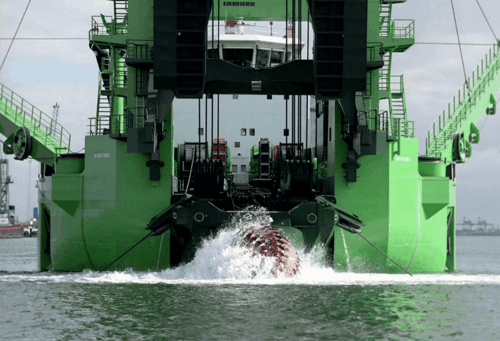

The Cutter Gear Bulkhead seal is designed for safeguarding the CSD’s cutter gear machine room. The Cutter Gear Bulkhead Seal is a proven, highly reliable sealing solution for 24/7 dredge operations. It is designed to keep you going and take the next step in both performance and reliability.

ADVANTAGES

- The flexibility and (bearing) support to manage 5 mm of radial displacement

- Minimal wear on lip seals and the support bearing

- Condition monitoring

- Planned maintenance while minimising the risk of sudden failure

- Modular, Made-to-Measure

HOW IT WORKS

Conventional seals are not able to perform under harsh dredging conditions that cutter suction dredgers (CSDs) encounter every day during their activities. For this sole purpose, Lagersmit has developed a highly reliable cutter gear bulkhead sealing solution, which can handle extreme bulkhead and shaft deformations.

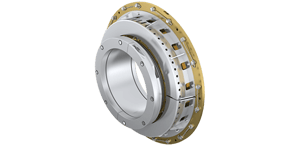

The Cutter Gear Bulkhead sealing system consists of a floating seal with a protective cover and lubrication system, equipped with all necessary sensors for controlling and monitoring the sealing system. The Cutter Gear Bulkhead seal is installed on large cutter shafts and is mounted on the bulkhead of the cutter gear machine room. Because the cutter shaft generally consists of several flange coupled shafts, the seal is made fully split.

The “floating” seal will follow the radial shaft movement by means of a segment with an integrated white metal slide bearing. This way, conditions for proper static alignment and run-out are met automatically. All oil and grease connections are made on the inboard side of the seal; no extra passages through the bulkhead are needed.

THE LUBRICATION SYSTEM

The lubrication system comprises a grease pump and a lube oil system. The lube oil system circulates the oil and controls pressure, flow and temperature in order to build up an appropriate lubrication film for the white metal slide bearing. Lip seals #3 and #4 also benefit from the conditioned oil flow, increasing the mean time between maintenance.

The lubrication system has a redundant pump set and filter, making it possible to perform maintenance while the dredging operation continues. The grease circuit is for lubricating the water-repellent lip seals when operating above the waterline. The constant grease supply together with the second water-repellent lip seal (#2) form a reliable barrier against water ingress.

Lagersmit is not only responsible for the development and production of the sealing system but also performs the installation of the seal and commissions the complete sealing system and system controls.