LIQUIDYNE® 3-STAGE

TABLE OF CONTENTS

LIQUIDYNE® 3-STAGE

The Liquidyne 3-Stage is specially developed for dredging pumps that process a polluted medium with abrasive media particles that are larger than 100 µm. The Liquidyne seals the pump shaft and uses an external flush to lubricate, cool, and clean the seal, while the drain flow enables condition monitoring.

APPLICATIONS

- Vertical sump pumps

- Slurry pumps

- Self-priming centrifugal pumps

- Diffuser pumps

- Booster pumps

- Split case pumps

- Concrete volute pumps

- Sewage pumps

- Vertical suspended pumps

- Axial pumps

- Fish-friendly pumps

ADVANTAGES

- Robust seal design

- Dirt retaining module

- Predictable lifetime due to condition monitoring

- Low power consumption

- Maximized maintenance intervals

- Hard Metal Layer (HML) coating for extra durable grooved liners

- Optional design: can be designed with divisible housing parts

This seal is mainly applied to dredging pumps, sewage water pumps, booster pumps and mining pumps.

<100 MICRON

6<PH<8

NO

RESTRICTION

NO

RESTRICTION

0<T<90°C

1<P<41

HOW IT WORKS

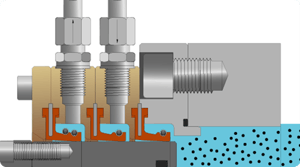

The Liquidyne seal is made up of different modules and fulfils the following functions:

- Sealing the pump shaft

- Reducing pressure

- Retaining dirt

The order of the modules can vary and depends on the specific application. The seal can be roughly divided into two parts:

- A grooved shaft sleeve that is clamped and rotates with the pump shaft;

- The stationary housing parts and rubber lip seals that are mounted against the pump housing.

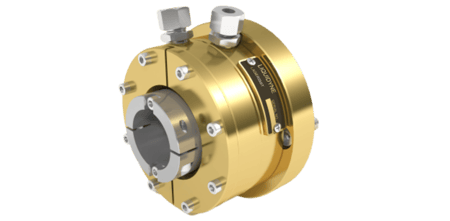

The Liquidyne 3-Stage is designed for large abrasive particles (larger than 100 µm) and uses an external flush to lubricate, clean and cool the seal. The water-lubricated Liquidyne lip seals run over a partially grooved shaft sleeve placed over the pump shaft. The helical shape of the grooves and peripheral speed (RPM) of the liner create water flow (similar to aquaplaning) between the grooves and the lip seal. The water flows from the pump side to the drain of the seal. The condition of the seal is monitored by measuring the water flow from the pump side to the drain of the seal. The Liquidyne 3-Stage is available for shaft diameters from 35 to 590 millimetres.

MATERIALS

The Liquidyne 3-Stage consists of a grooved shaft sleeve (stainless steel) with a hard metal wear layer (HML), housing parts (stainless steel), NBR lip seals and Hastelloy® C4 springs.

OPTIONAL

Low-pressure pumps can optionally use a liner with a smooth and flat surface instead of a grooved surface.

CUSTOMISATION

Are our standard solutions not suitable for your application? Our engineers are more than happy to develop a custom-made sealing product!

PREDICTABLE LIFETIME

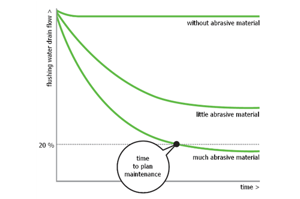

One of the main benefits of the Liquidyne is that the condition monitoring function is not just to simply monitor the condition of the seal, but it also creates a predictable lifetime. How? Over time, the grooves on the shaft sleeve gradually wear down. Less water is transported over the shaft sleeve and the amount of water leaving the drain decreases. When the drain flow is at 20% of the initial flow, maintenance needs to be planned.

By keeping track of this drain flow you can plan maintenance more efficiently, minimising the risk of sudden pump failure, optimise mean time between maintenance and reduce costs.