PUMP GEAR BULKHEAD

PUMP GEAR BULKHEAD

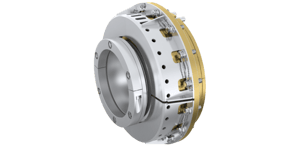

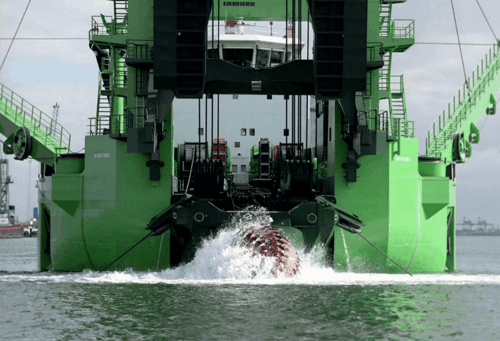

The Pump Gear Bulkhead seal is designed to safeguard the CSDs pump gear machine room. This bulkhead sealing solution can handle large bulkhead and shaft deformations and can operate in abrasive environments at draughts of 16 meters.

ADVANTAGES

- The flexibility and (bearing) support to manage 5 mm of radial displacement

- Pressure compensation

- Zero emissions

- Minimal wear

- Condition monitoring

- Planned maintenance while minimizing the risk of sudden failure

- Modular, Made-to-Measure

HOW IT WORKS

The Pump Gear Bulkhead sealing system consists of a floating seal with a protection cover and a lubrication system with a Supreme Ventus® system, which are equipped with all necessary sensors for controlling and monitoring the seals. The Pump Gear Bulkhead seal is installed on the underwater pump shaft and is mounted to the bulkhead of the underwater pump gear machine room.

The “floating” seal will follow the radial shaft movement by means of a segment with an integrated white metal slide bearing. This way conditions for proper static alignment and run-out are met automatically. All oil connections are made on the inboard side of the seal; no extra passages through the bulkhead are needed.

THE LUBRICATION SYSTEM

The lubrication system comprises two lube oil systems. The lube oil system circulates the oil and controls pressure, flow and temperature in order to build up an appropriate lubrication film for the white metal slide bearing. The lubrication system has a redundant pump set and filter, making it possible to perform maintenance while the dredging operation continues.

Lagersmit is not only responsible for the development and production of the sealing system, but also performs the installation of the seal and commissions the complete sealing system and system controls.