COSUN BEET COMPANY

GLAND PACKING CONVERTED INTO A LIQUIDYNE® SEAL

COSUN BEET COMPANY

The greenest beet processor in Europe: that’s the sustainable ambition that Cosun Beet Company pursues every day. As well as developing, producing and selling sugar and sugar specialities, it processes every part of the sugar beet into natural ingredients for the food, bioplastics and energy industries.

FROM GLAND PACKING TO LIQUIDYNE SEAL

Due to the good experiences, we replaced two gland packings for Liquidyne seals in the summer of 2018. Cosun Beet Company had problems with the leakage of these slurry pumps. The shaft sleeve had to be replaced every 4 months. For this, the pumps had to be completely decoupled and overhauled in the workshop. The maintenance costs were high and decreased the availability of the pump. The gland packing had to be checked daily to avoid damage to the bearing. Leakage was also undesirable in the context of safety. With the Liquidyne, the maintenance interval has been considerably extended, leaks are a thing of the past and the workplace remains clean and safe.

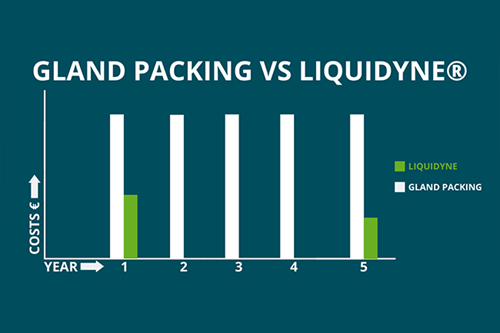

SAVINGS ON MAINTENANCE COSTS

By installing the Liquidyne, Cosun Beet Companysaves time and money on maintenance costs for sealing the slurry pump. With the Liquidyne, it is expected that after 5 years only the spare parts and grooved bush need to be replaced. Compared to gland packing, this saves 15 times on maintenance work and spare parts.