Stern Tube Seals

TABLE OF CONTENTS

STERN TUBE SEALS

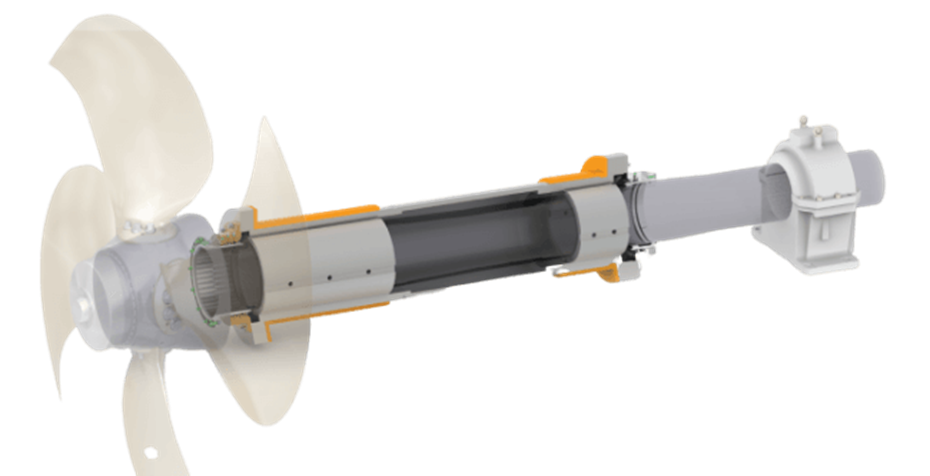

A stern tube with bearings radially supports the propeller shaft from the main engine. The stern tube is a hollow tube that accommodates the bearings, the seal boxes, and the propeller shaft.

The stern tube is filled with oil, grease or water, forming a barrier between the water outside and the engine room inside the vessel. The stern tube mainly consists of the following parts:

The tube itself

Connection flanges (forward and aft)

Bearings (forward and aft)

Smaller pipes for temperature sensors

Lubrication of the aft seal (or drain pipes for air-type seals)

Forward seal (engine room side)

Aft seal (water side)

Our Supreme® stern tube seals are used in seagoing vessels, inland vessels, yachts, cruise ships, fishing vessels, ferries and dredgers. They are produced with high-quality housing parts, rubber lip seals and liners.

HOW STERN TUBES WORK

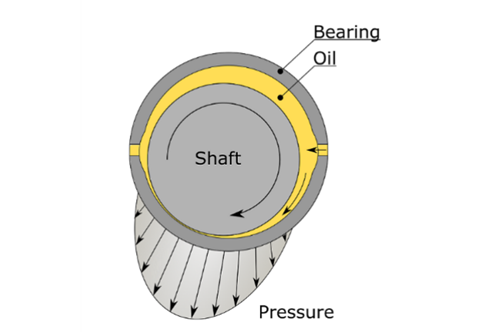

The function of the stern tube bearings is to carry the radial loads of the propeller shaft and to protect the shaft against wear. In case of an oil-lubricated bearing, this is achieved by creating an oil film between the bearing and the propeller shaft. When the propeller shaft is rotating, nearby oil will follow the circumferential movement of the propeller shaft. At sufficient shaft speed, the oil will flow from the supply holes in the bearing along with the shaft towards the bottom of the bearing. Here it is forced between the narrowing space between bearing and shaft, which creates lift. When the shaft speed is high enough, there will be no metallic contact between the shaft and bearing. This principle is called hydrodynamic lubrication.

Every stern tube design is customised according to the customer’s requirements. Because the stern tube can be fully equipped with piping, bearings and seals, the installation can be done within a day. There are various types of stern tube systems available and when making your choice you have to take several factors into consideration.

LUBRICATION

First, an important factor is the intended lubrication medium. Oil-lubricated stern tube systems are the most common but occasionally ship owners require a water-lubricated or grease-lubricated stern tube system.

SHIP DESIGN

Second, depending on the ship design, the stern tube can be supported with struts or can be positioned within the ship’s hull. Often the surrounding sea water will suffice for dissipating the heat from the stern tube oil. The heat generated by bearing friction is then transferred through the shaft and the stern tube inner surfaces towards the outer surfaces of the stern tube, adjacent to the sea water. If the natural heat dissipation is insufficient and the oil temperature needs to be controlled, an external lube oil unit can be acquired for circulating and cooling the stern tube lube oil. Circulating the oil also provides the means to separate water from the oil, in case of water ingress.

INTERNAL STRESSES

Third, it is inevitable that stresses occur in the stern tube during installation and operation due to thermal growth. To prevent internal stresses, the forward end of the Lagersmit stern tube is free to extend in an axial direction, without compromising the strength and stiffness, or the attachment to the hull.

We offer complete stern tube systems with the bearings, piping and seals already in place. This will make the installation much easier and save you valuable time and money. The design of the ster

OTHER ADVANTAGES

Our stern tube systems are

Delivered fully assembled on site

Compatible with Lagersmit’s Supreme Ventus sealing system

Ready-machined in a controlled environment

Easily installed by means of a resin casting

Interfaced with Lagersmit-type seals

In addition to stern tube bearings, we also deliver intermediate shaft bearings to support longer shafts in a driveline. If an open or closed water stern tube system is required, please call us for further information.

STERN TUBE SEALS FOR INLAND AND SEAGOING VESSELS

Lagersmit supplies stern tube seals for two categories; the Supreme seals for inland vessels and the Supreme seals for seagoing vessels. The outboard or aft stern tube seal is located at the aft end of the stern tube. The seal’s housing is connected to the ship’s stern tube bossing and the liner is fixed on to the propeller hub. The aft seal prevents seawater from contaminating the stern tube oil, which may possibly jeopardise the lubrication properties of the oil, leading to extensive bearing wear. The aft seal also prevents oil leaking into the marine environment.

INLAND VESSELS

For inland vessels we recommend the Supreme Inland Vessel Aft and Forward sealing solution. The aft seal contains three lip seals. The first two lip seals form a barrier against water ingress and the third one prevents oil leakage from the stern tube into the surrounding water.

Because vessels for inland waterways don’t have to cope with highly corrosive seawater, the housing parts of the aft seal are made out of cast iron. All four housing parts of the aft seal are bolted together, all at once. The same goes for the forward seal. The inboard or forward seal is located at the forward end of the stern tube and is connected to the aft peak bulkhead inside the engine room. The forward seal contains two lip seals preventing oil leaking from the stern tube into the engine room. The chamber between the lip seals can be filled with oil or grease for lubricating the outermost lip seal.

SEAGOING VESSELS

The Supreme Standard Aft (STA) and Supreme Standard Forward (STF) seal are developed for seagoing vessels. The aft seal on a seagoing vessel is in contact with highly corrosive seawater. Therefore, the housing parts are made out of bronze. The housing parts of the Supreme Forward seal are made out of cast iron.

The STA and STF have the same configuration of the lip seals as the lip seals from the Supreme Standard for Inland Vessels, and perform in the same way. The main difference, apart from the material of the aft seal, is that the housing parts are fixed independently of each other. This enables easy bonding of the lip seals when the vessel is in dry dock, saving a lot of precious time. This isn’t necessary for inland vessels, because for inland vessels it’s quite easy to remove the propeller so the entire seal can be disconnected.

The STF is equipped with a lube oil tank and a scraper which is located in between the lip seals. The scraper forces the oil to circulate through the lube oil tank, providing cooling when the shaft is turning.

PRODUCTS

Extra security against oil leakage into the marine environment

Extra security against oil leakage into the marine environment

More about the SUPREME® SEAGUARD

Guarantees zero emissions of oil for seagoing vessels.

Guarantees zero emissions of oil for seagoing vessels.

We believe a seal should deliver top performance, keep you going and offer you Peace of Mind. This idea led to the development of the Supreme® stern tube seals. Introduced in the 1980s and further developed ever since, Supreme stern tube seals offer a ‘plus’ to many propulsion systems and vessels worldwide.

The Supreme stern tube seals are produced with high-quality housing parts, lip seals and liners. Our Modular, Made-to-Measure philosophy enables us to deliver customer-specific designs combined with short quotation, lead and delivery times. In addition, the Supreme seals are suitable for both new-build and retrofit applications.

REFERENCES

.jpg?width=200&name=logo-berg-propulsion%20(1).jpg)