Thruster Seals

TABLE OF CONTENTS

THRUSTER SEALS

Thruster seals protect your thruster against water ingress and oil leakage to the outside environment. Because there are many different types of thrusters, we design a custom-made sealing solution for every application.

WHAT IS A THRUSTER?

A thruster is a propulsion system that is used to make ships more maneuverable. Because thrusters can be rotated, a rudder is no longer necessary. There are many different kinds of thrusters, for example:

Azimuth thrustersAzipull thrusters

Tunnel thrusters

Bow thrusters

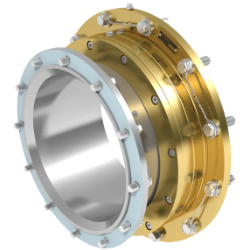

SUPREME® THRUSTER SEALS

Lagersmit delivers reliable solutions for all kinds of new and existing thrusters. This goes from basic solutions up to pressure-compensating, zero emissions, and 100% condition-monitored solutions. There are targeted designs for thrusters with varying depths, a small build-in length, and heavy-duty operations.

Our Supreme thruster seals are suitable for

Fully oil-filled lower gearboxes

Spray-lubricated lower gearboxes

Pressurized oil-filled thrusters

The Supreme thruster seals are produced with high-quality housing parts, lip seals, and liners. Our Modular, Made-to-Measure philosophy enables us to deliver customer-specific designs combined with short quotation, lead and delivery times.

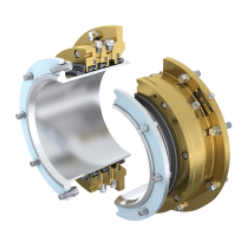

HOW IT WORKS

The chamber between the two oil-repellent lip seals is filled with oil and the resulting pressure effectively keeps water outside and oil inside the thruster gearbox. Even in the unlikely event of damage to the water repellent lip seals, the system will still prevent any water ingress into the thruster’s lower gearbox. The oil barrier will lose its overpressure and the oil level drops, triggering the low level alarm and oil/monitoring tank to create a pressurised oil barrier.

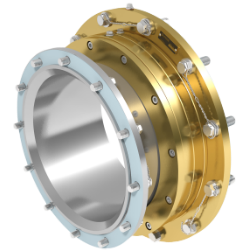

RETROFIT

Existing thrusters can be enhanced with a broad set of retrofit possibilities. In need of a new or retrofit thruster seal? Our experts are ready to find the best possible sealing solutions for you!

Thruster manufacturers know they can depend on our highly reliable seals for their applications. Lagersmit is continuously working to improve its standards and give light to innovations for monitoring the seal condition.

The seal has been approved by DNV GL to be in line with the Vessel General Permit.

.jpg?width=200&name=logo-berg-propulsion%20(1).jpg)