Did you know our company name is derived from the Dutch word ‘lager’, which means bearing? It’s time to highlight were it all started: the bearings. Since 1856 we have been delivering high quality castings and from the 1960s we expanded our product range with sealing solutions. This blog focuses on the bearings and gives you more information about the working principles, how our bearings deliver you Peace of Mind and what the advantages of using white metal lining are.

STERN TUBE BEARINGS: REFRESH YOUR MIND

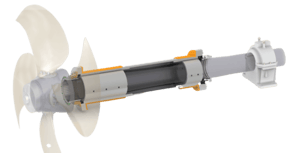

In marine propulsion plants, sliding bearings are used to support the propeller shaft and takes up the radial forces generated by the propeller. There are various types of stern tube bearings available, for the selection you have to take several factors into consideration. One important factor is the intended lubrication medium. Oil-lubricated systems are the most common, but ship owners also use water-lubricated and grease-lubricated systems.

HOW IT WORKS

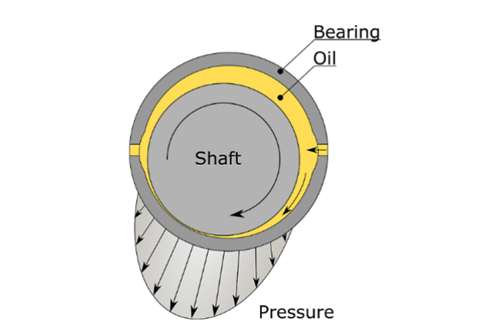

The function of the stern tube bearings is to carry the radial loads of the propeller shaft and to protect the shaft against wear. In case of an oil-lubricated bearing, this is achieved by creating an oil film between the bearing and the propeller shaft. When the propeller shaft is rotating, nearby oil will follow the circumferential movement of the propeller shaft. At sufficient shaft speed, the oil will flow from the supply holes in the bearing along with the shaft towards the bottom of the bearing. Here it is forced between the narrowing space between bearing and shaft, which creates lift. When the shaft speed is high enough, there will be no metallic contact between the shaft and bearing. This principle is called hydrodynamic lubrication (image 1).

Image 1: Hydrodynamic lubrication

How Lagersmit’s bearings deliver you Peace of Mind

Aft and forward stern tube bearings

We offer white metal lined aft and forward stern tube bearings, suitable for oil- and grease-lubricated applications.

Benefits:

- Design based on proven technology

- Delivered pre-machined for flexibility on site

- Suitable for both new build or retrofit applications

- Can be customised with various materials and options (e.g. temperature sensors) to fit the intended application

Intermediate shaft bearings

In addition to stern tube bearings, we also deliver intermediate shaft bearings to support longer shafts in a driveline.

Benefits:

- Self-lubricating, so no additional piping or oil pumps are required

- Easy installation due to split design

The advantages of white metal lining

Lagersmit offers stern tube bearings that are made of a cast iron bush, lined with white metal. The white metal lining is made by means of centrifugal casting. This process has multiple benefits on the material structure:

- Due to the centrifugal forces during casting, possible gasses or impurities will be forced to the inner diameter. These can easily be removed after the casting by machining.

- The lighter elements will settle closer to the inner diameter and the heavier elements to the outside. This results in a wear resistant running surface with a though and soft base layer adhering to the cast iron bush.

Other advantages of white metal lining are:

- Good sliding properties

- Low sensitivity to edge pressure due to the soft lining material

- Good emergency running properties and protection of the shaft material

There are two types of white metal; lead based and tin based. In most cases lead based white metal will be sufficient and the most economic option. Tin based white metal is more suitable when dynamic loads can occur. In case there are restrictions on the use of lead as a bearing material, tin based white metal can also be used as an alternative.

This was part one of the blog, ‘The complete stern tube and sealing system’. In part two we focus on the stern tubes and give you more information about the working principles and how our total stern tube and sealing system delivers you Peace of Mind.