Stork

GLAND PACKING CONVERTED INTO A LIQUIDYNE® SEAL

STORK

As a pump manufacturer with a rich and long history, Stork has ample experience in designing pumps. The shaft seal is an essential part of our pumps. In the past, Stork Pumps often used compression gland packing and mechanical seals.

The shaft seal is an essential part of our pumps. In the past, Stork Pumps often used compression gland packing and mechanical seals.

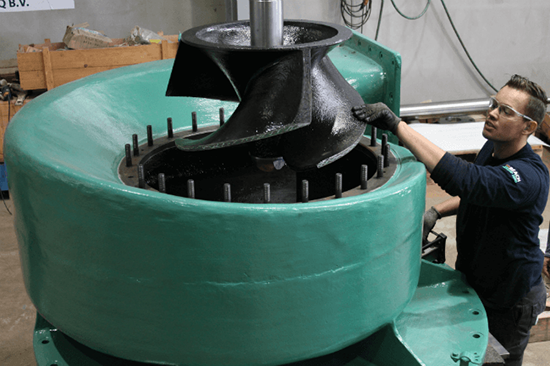

As recently as 2018, we converted a compression gland packing into a water-lubricated Liquidyne seal for a pumping station pump. This involved a Stork pump from 1969 equipped with a grease-lubricated compression gland packing. The Water Board (Waterschap) prescribed a water-lubricated lip seal, in part because of its target to eliminate the use of grease in surface water. As a pump manufacturer, we always carefully weigh up our options. We have chosen a pump shaft seal from Lagersmit, partially because of our positive previous experiences with the quality of products delivered, the service offered, and options for joint, customer-specific engineered solutions.

Adjustments have been made to the pump parts, and the Liquidyne® seal – delivered on time – has been installed. The pump, complete with the new Liquidyne seal, was then successfully commissioned and tested in the pumping station.