TABLE OF CONTENTS

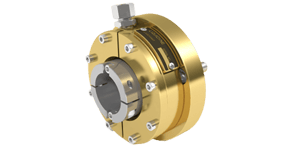

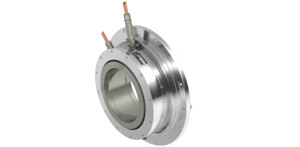

PUMP SHAFT SEALS

- Predictable lifetime due to condition monitoring

- Low power consumption

- Maximised maintenance intervals

- Especially for heavily polluted pump water

- Maximised maintenance intervals

- Predictable lifetime due to condition monitoring

- Closed flush system

- Condition monitoring

- Minimal consumption

MINING

The mining industry is characterized by remote locations with harsh conditions and rarely has clean water facilities. Mining pumps need a robust sealing solution that can handle abrasive media with little flushing water. The Liquidyne® pump shaft seal reduces friction on the shaft and uses only a fraction of flushing water compared to gland packings.

LIQUIDYNE® PUMP SHAFT SEALS

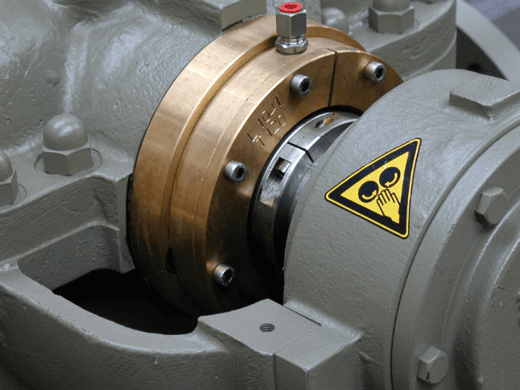

Released in 1983, the water-lubricated Liquidyne pump shaft seal was initially intended for heavy-duty dredge pumps. The seal can handle above-average axial and radial play thanks to its robust design. It is suitable for pumps that have to deal with severe shocks and vibrations, incorrect alignment, and abrasive media. The Liquidyne increases the pump’s lifetime and leads to a longer mean time between maintenance (MTBM) thanks to its robustness. Condition monitoring adds predictability and makes your operation more secure.

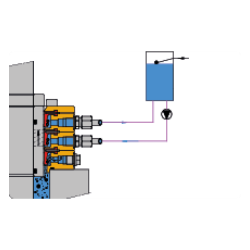

The Liquidyne® is a sealing solution that needs to be flushed during heavy-duty operations, such as when dealing with abrasive media. For situations in which no flush supply is present, Lagersmit has developed a Closed Loop Lubrication Unit (CLLU) to circulate the external flush medium. Circulating the flushing medium minimizes the total consumption of the seal and increases the durability of the Liquidyne seal, as flush water is filtered.

Are you curious about the differences between the Liquidyne, gland packing, and mechanical seal? Please read it in our blogs!

Liquidyne VS mechanical seal

ADVANTAGES:

Predictable lifetimeEnergy savings

Easy to maintain

The Liquidyne has a predictable lifetime due to the condition monitoring function. In addition, the pump shaft seal is also environmentally friendly thanks to the water-lubricated system that saves energy through reduced friction on the shaft.

OUR CUSTOMERS